Call Us Now08045802018

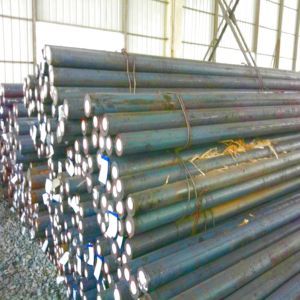

AISI 4130 Round Bars

70 INR/Kilograms

Product Details:

- Type AISI 4130 Round Bars

- Material Steel

- Grade AISI 4130

- Click to view more

X

AISI 4130 Round Bars Price And Quantity

- 50 Kilograms

- 70 INR/Kilograms

AISI 4130 Round Bars Product Specifications

- AISI 4130

- Steel

- AISI 4130 Round Bars

AISI 4130 Round Bars Trade Information

- Cash Advance (CA), Cash in Advance (CID)

- 1 Kilograms Per Week

- 1 Days

- Yes

- Free samples are available

- All India

Product Description

We are an outstanding supplier, importer, stockiest and trader of AISI 4130 Round Bars. Used in numerous construction purposes, these rods are constructed from superior quality material at par with defined standards and parameters. These bars are provided in various sizes to meet diverse demands of the client. AISI 4130 Round Bars have emerged as the preferred choice of many clients and the main features that are responsible for this immense admiration are longevity, incredible tensile strength and cost effectiveness.

Chemical Composition :-

- Carbon : Min 0.28, Max 0.33%

- Silicon : Min 0.15, Max 0.35%

- Manganese : Min 0.40, Max 0.60%

- Molybdenum Min 0.15, Max 0.25%

- Chromium : Min 0.80, Max 1.10%

- Phosphorous : Max 0.035%

- Sulfur : Max 0.04%

Equivalent Grades :-

- Standard AISI/SAE 4130

- WERKSTOFF 1.7218

- BS 708A25, 708M25

- JIS SCM430

- DIN 25CrMo4

Technical Specifications :-

- Ratio of forging : minimum 3:1

- Melting process : EAF/BOF+LF+VD resulting in ingots

- Ultrasonic test : As per SEP1921 Class C/c or D/d

- Grain size of final product : According to ASTM E112 more than 5

- Both end cut by saw

Features of AISI 4130 Round Bars :-

- Durable

- Reasonable rates

- Superb performance

Superior Strength and Reliability

AISI 4130 Round Bars offer impressive tensile strength and resilience, making them essential materials for construction. Their alloyed composition ensures durability, even under continuous stress. As a preferred choice among designers and engineers, these bars contribute to safe and robust structures.

Versatile Applications in Construction

From building frameworks to mechanical components, AISI 4130 Round Bars are adaptable to a variety of construction needs. Their shape and steel grade facilitate easy machining, welding, and forming while maintaining structural integrity, even in challenging conditions.

FAQs of AISI 4130 Round Bars:

Q: How are AISI 4130 Round Bars used in construction projects?

A: AISI 4130 Round Bars are commonly used to reinforce structures, manufacture machinery components, and support frameworks due to their robust strength and weldability. Their round shape allows for precise engineering and reliable load-bearing capacities.Q: What is the primary advantage of grade AISI 4130 and 4140 steel in round bars?

A: The main benefits of these grades include high toughness, excellent fatigue resistance, and improved weldability that make them ideal for demanding construction and engineering applications.Q: When should AISI 4130 Round Bars be selected over other material types?

A: AISI 4130 Round Bars should be chosen when projects require exceptional strength, good machinability, and resistance to wear, especially in heavy-duty structural or mechanical environments.Q: Where can I purchase AISI 4130 Round Bars in India?

A: You can obtain AISI 4130 Round Bars from reputable distributors and importers in India who specialize in construction-grade steel supplies, ensuring quality and compliance with industry standards.Q: What is the process for importing AISI 4130 Round Bars into India?

A: Importers in India typically source these round bars through accredited global manufacturers, following standardized shipping, inspection, and customs procedures to guarantee the product meets required specifications.Q: How does the brown color of AISI 4130 Round Bars affect their usage?

A: The brown color of these bars is primarily due to their steel composition and finishing process. It does not impact their performance or durability in construction-related applications.Q: What key benefits do AISI 4130 Round Bars provide to construction and engineering sectors?

A: These round bars offer longevity, reliability, and adaptability, reducing maintenance needs and ensuring optimal safety in heavy-use environments. Their mechanical properties are well-suited to a wide array of structural challenges.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'AISI Series Steel Round Bars' category

Back to top

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese